| Parameter | Value |

|---|---|

| Inner & Outer Diameter |

Accurate ID and OD ensure a tight interference fit between the shaft and the mounted component. |

| Material | Manufactured from high-grade alloy steel or stainless steel for superior strength and durability. |

| Hardness |

Typically 50–60 HRC, providing excellent wear resistance and long service life. |

| Wall Thickness | Designed to withstand high compressive forces during shrink fitting without deformation. |

| Surface Finish & Tolerance | Precision-ground surfaces with tight tolerances (e.g., ±0.01 mm) ensure reliable strain measurements |

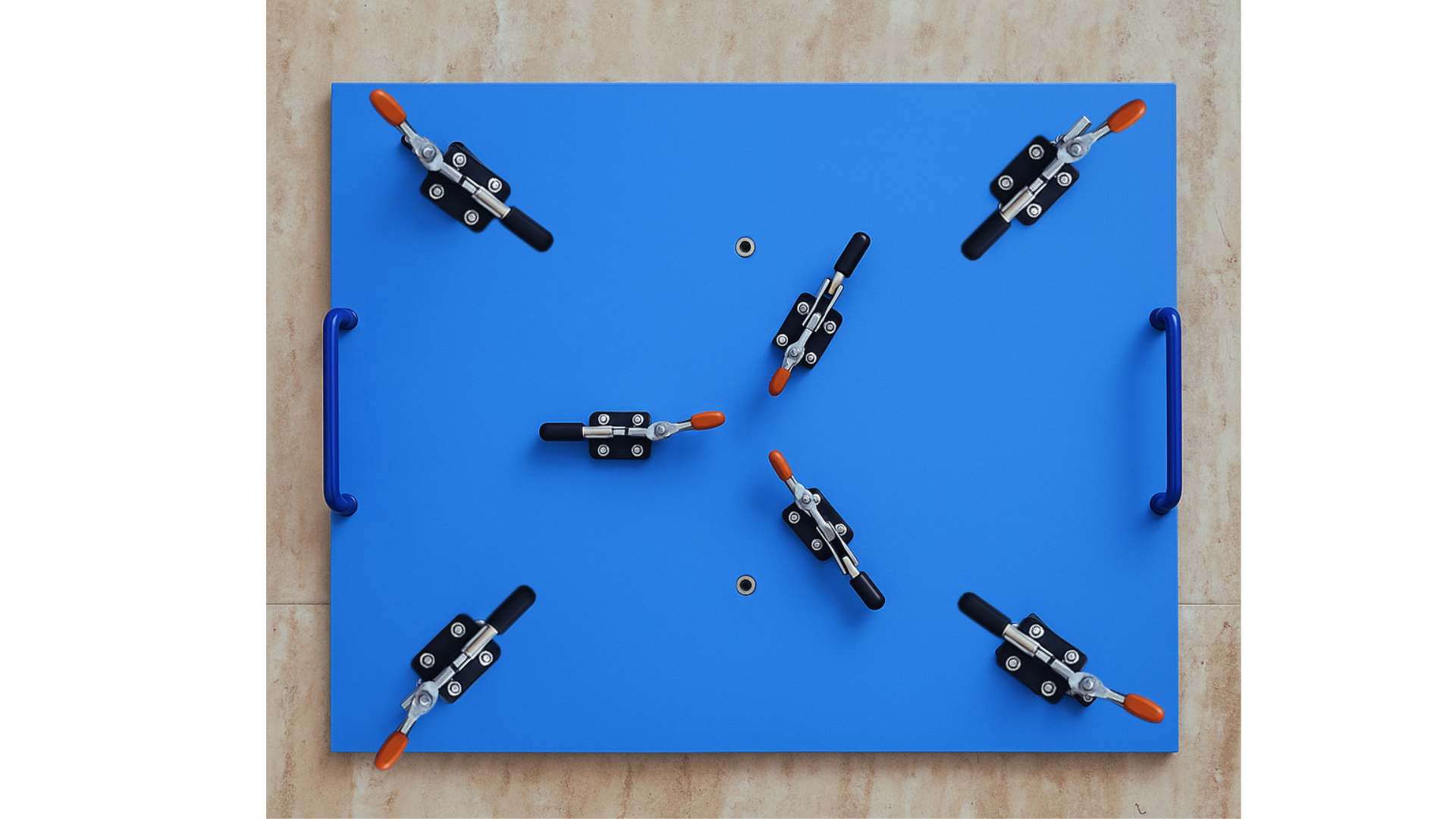

| Base Plate Material | Polypropylene |

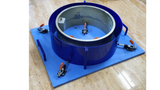

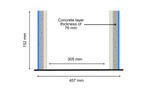

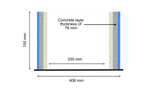

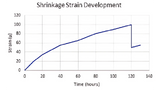

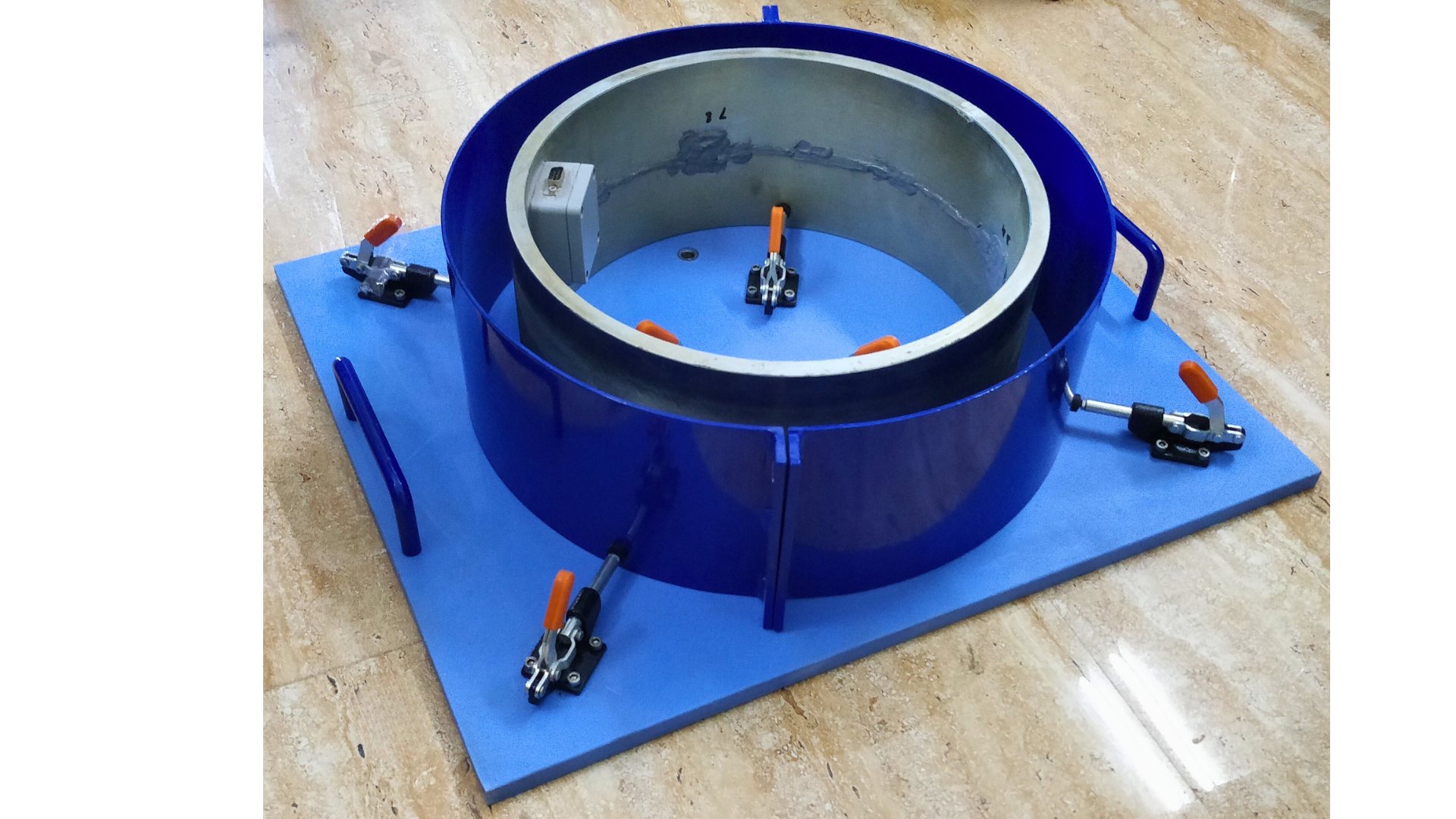

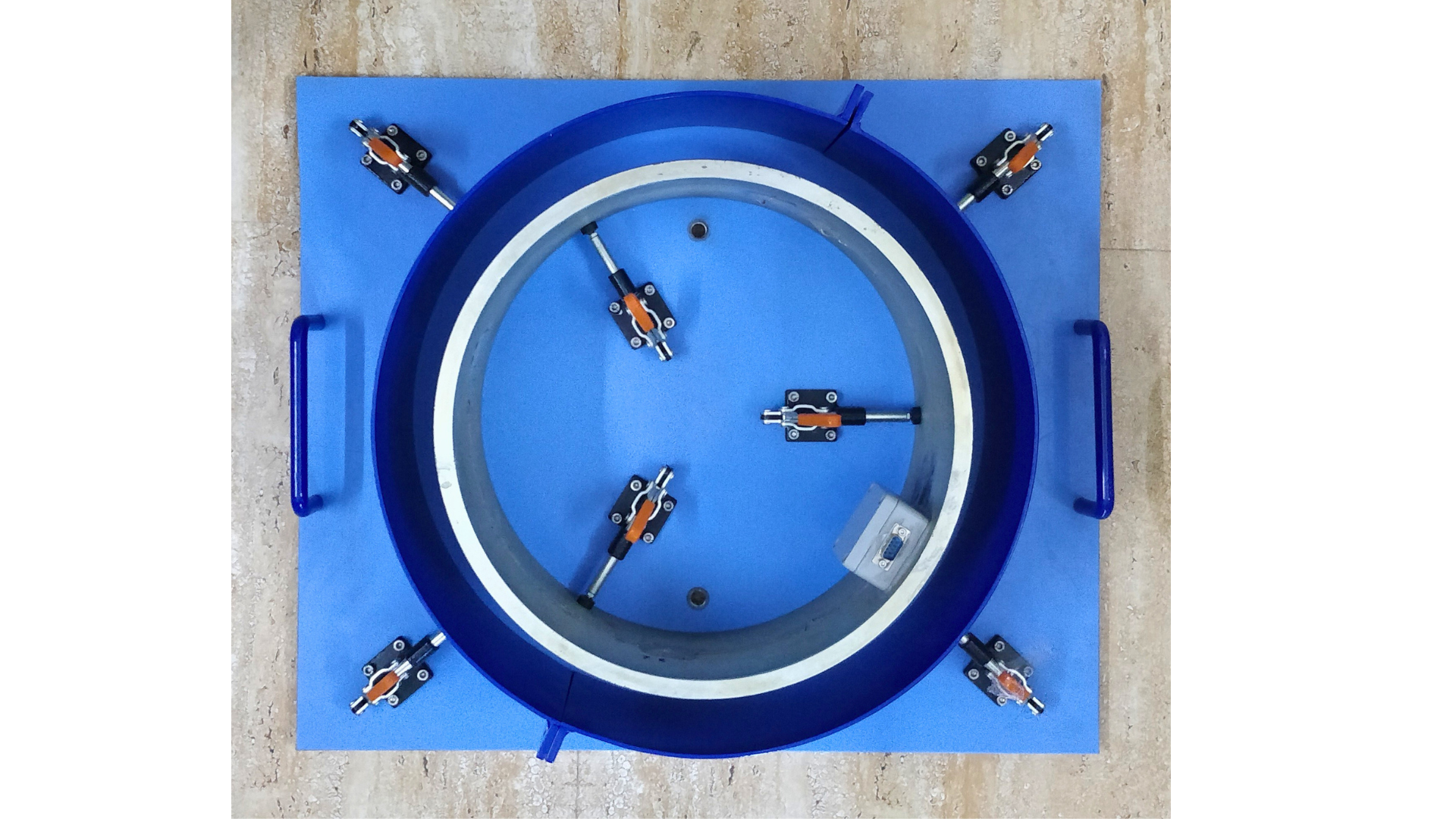

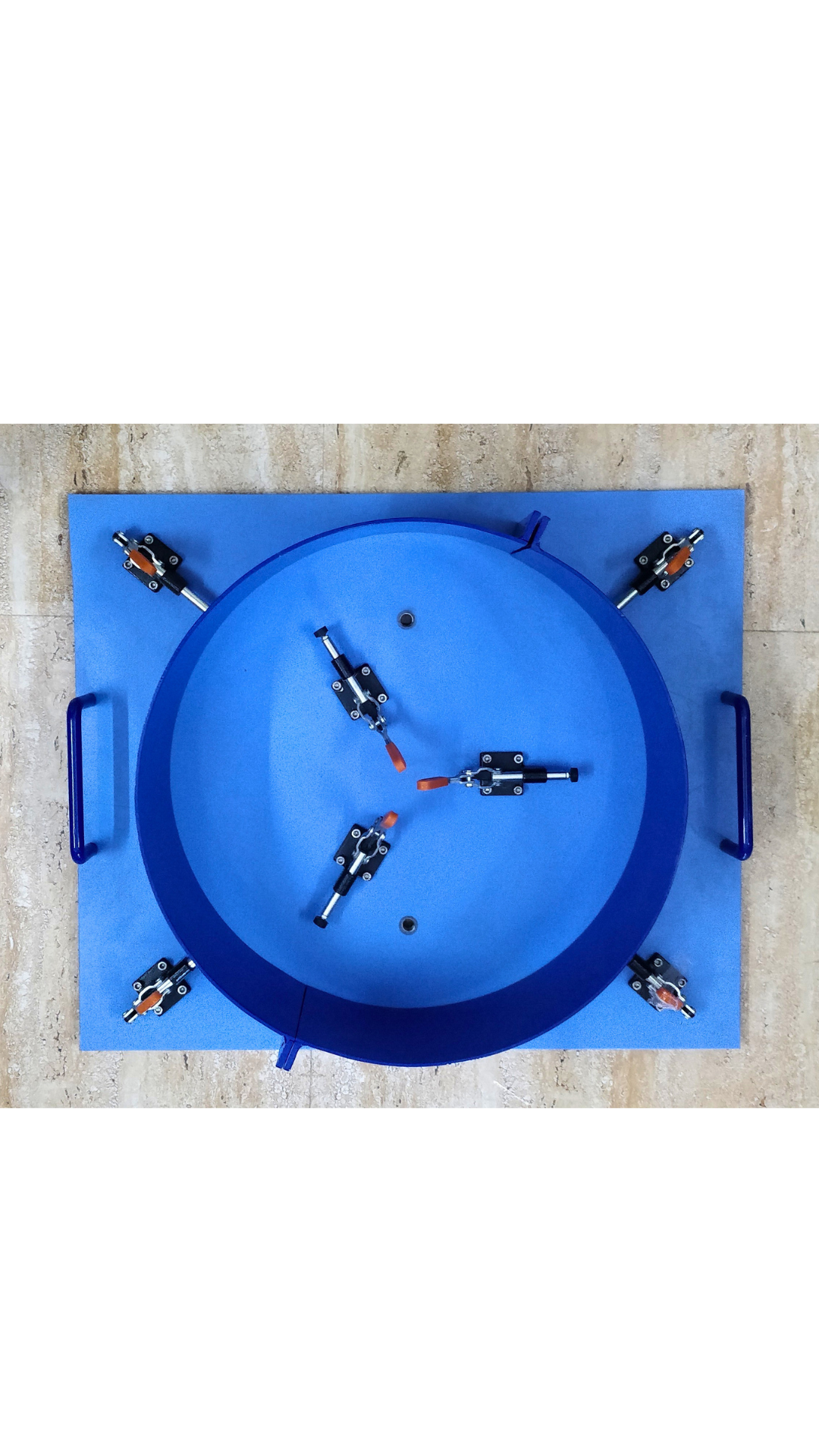

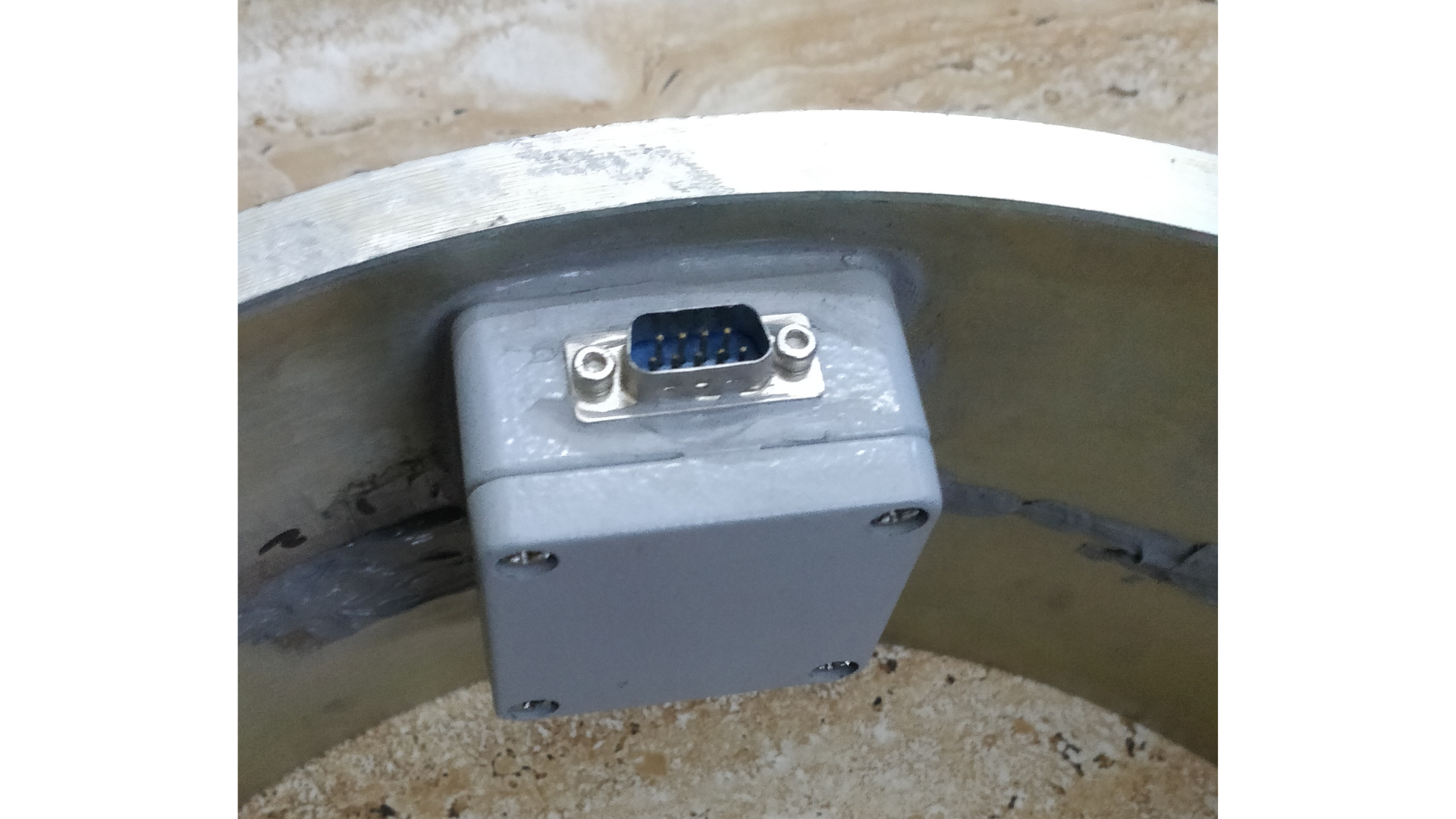

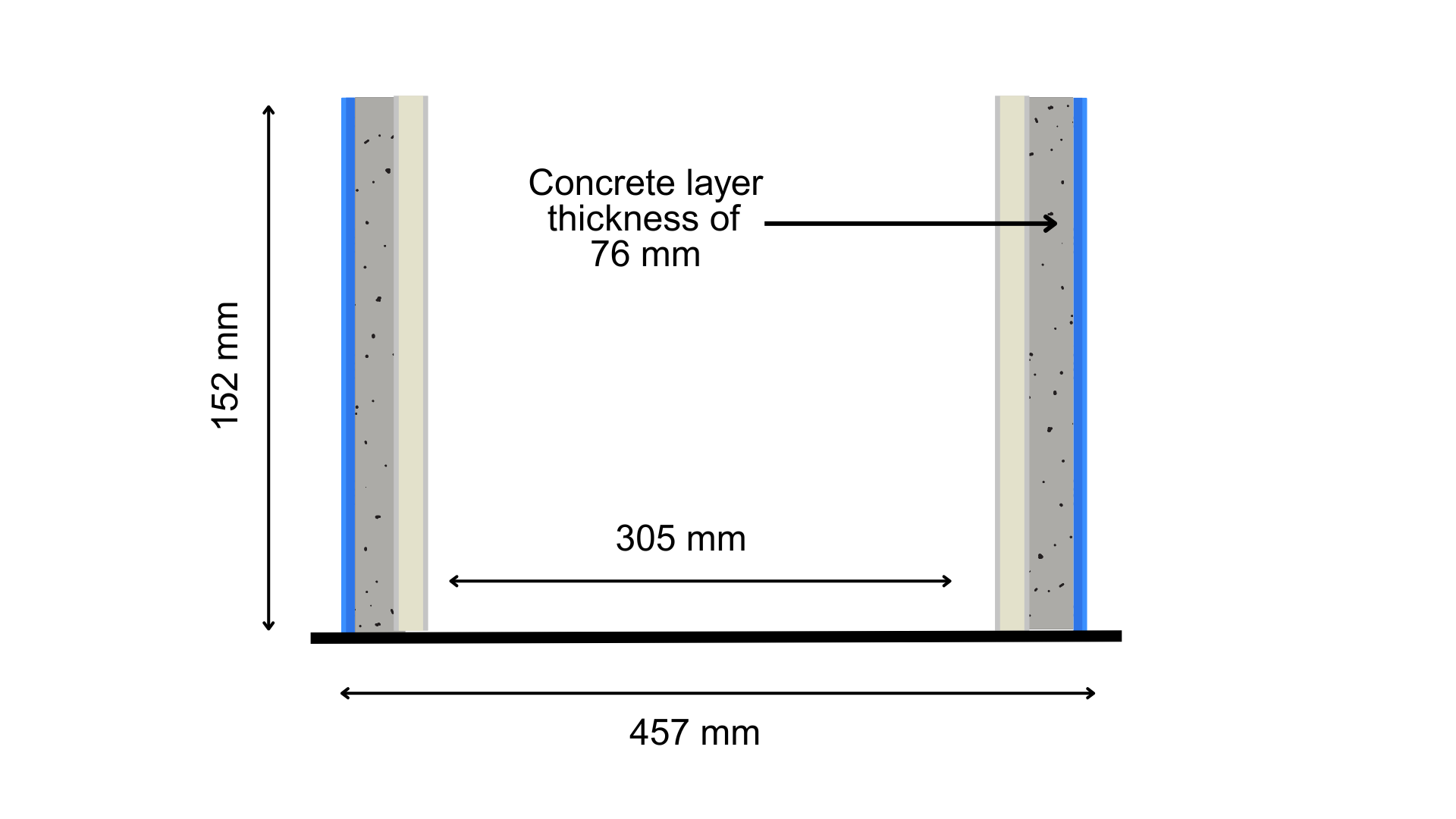

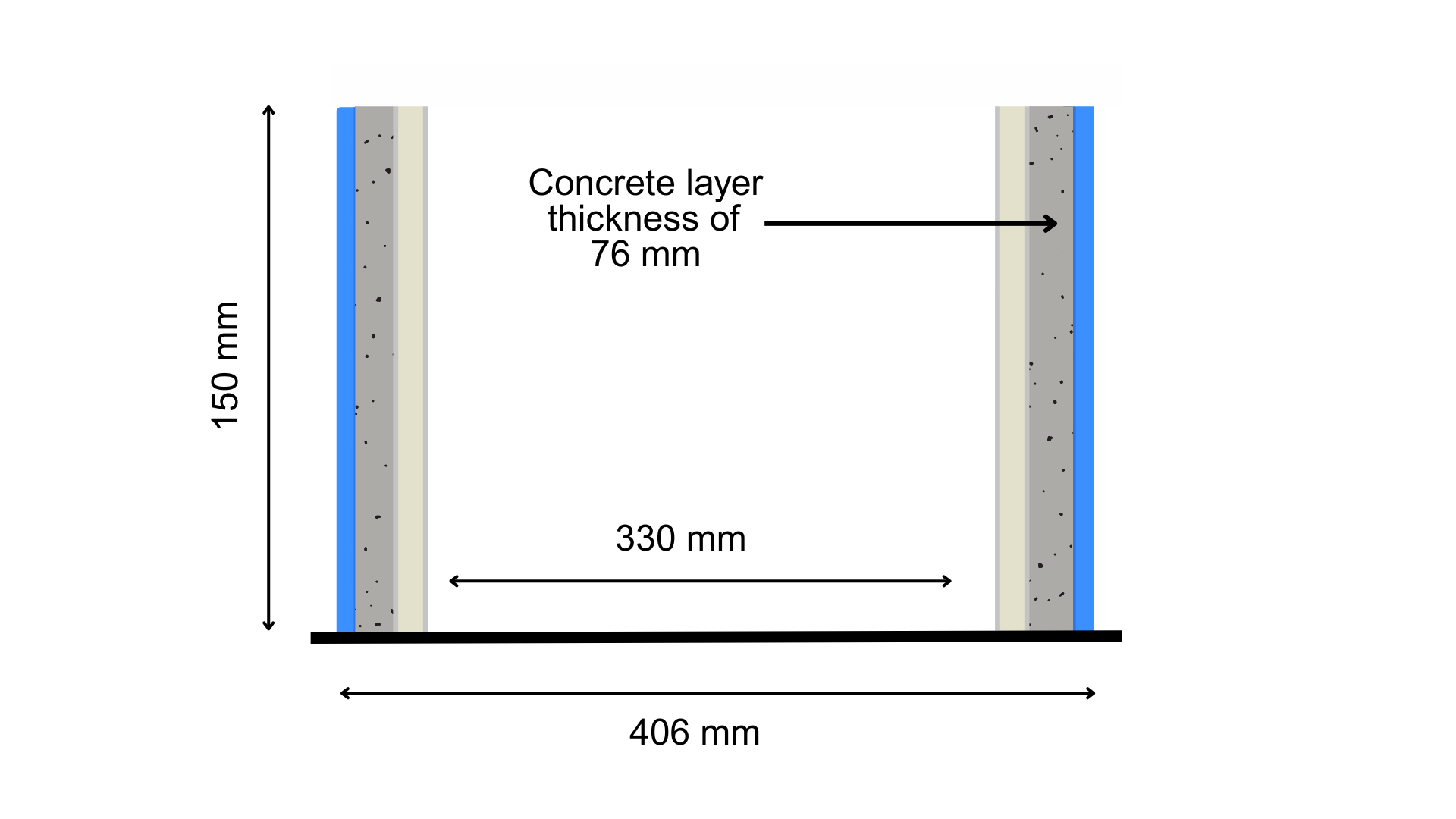

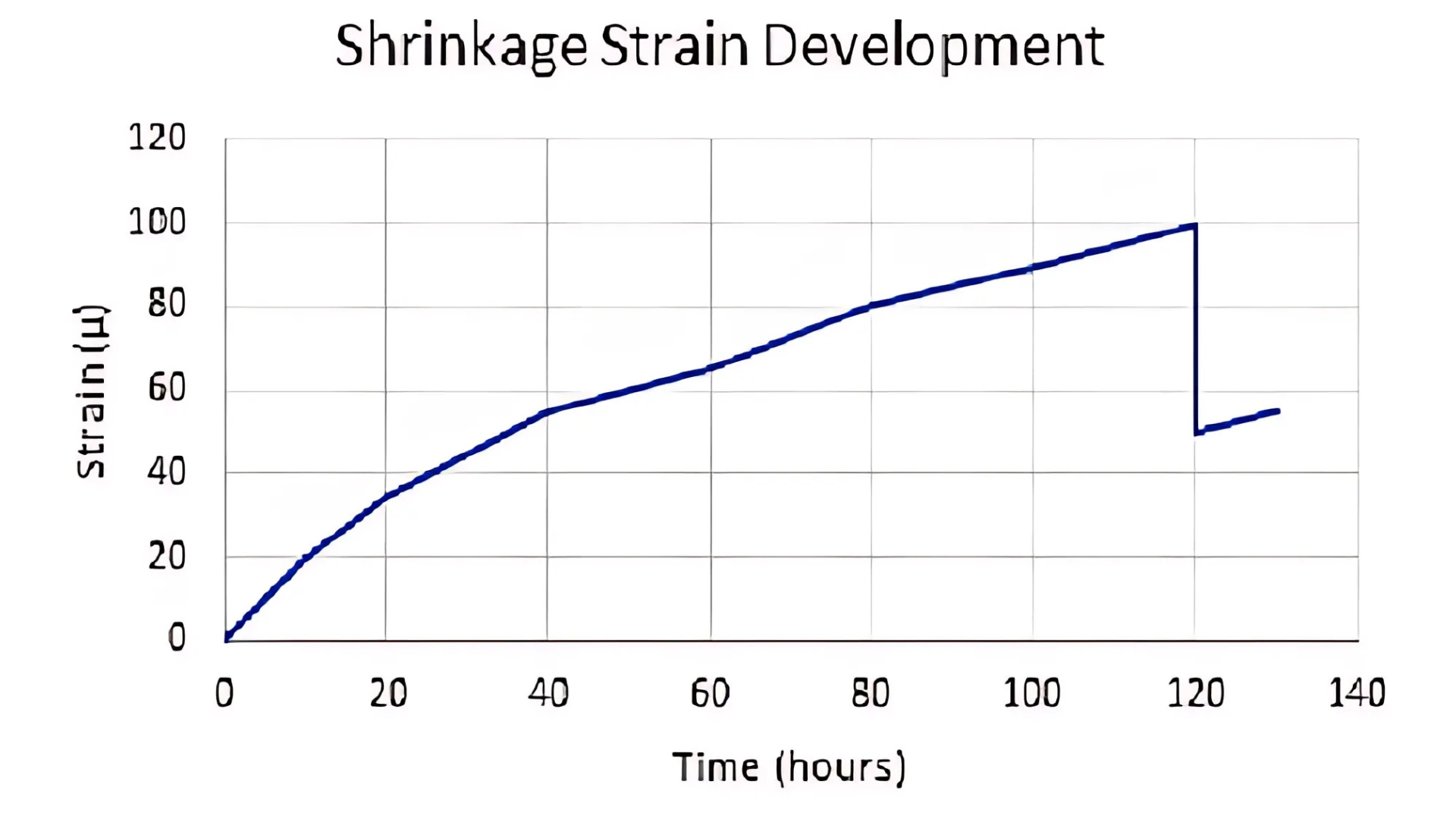

Evaluate cracking potential with unparalleled precision using our meticulously engineered Shrinkage Ring Assemblies. Designed specifically for restrained shrinkage testing of mortar and concrete specimens, these rings deliver consistent, reliable data on tensile stress characteristics and cracking age. Manufactured to strict specifications in full compliance with ASTM C1581 and AASHTO T334-08 standards, our Shrinkage Rings provide researchers and quality control professionals with definitive insights into material performance under real-world conditions.

Datasheet can be downloaded from the documents section.

Shrinkage ring prices depend on dimensions, material grade, and any custom machining requirements.

Data Sheet

| Parameter | Value |

|---|---|

| Inner & Outer Diameter |

Accurate ID and OD ensure a tight interference fit between the shaft and the mounted component. |

| Material | Manufactured from high-grade alloy steel or stainless steel for superior strength and durability. |

| Hardness |

Typically 50–60 HRC, providing excellent wear resistance and long service life. |

| Wall Thickness | Designed to withstand high compressive forces during shrink fitting without deformation. |

| Surface Finish & Tolerance | Precision-ground surfaces with tight tolerances (e.g., ±0.01 mm) ensure reliable strain measurements |

| Base Plate Material | Polypropylene |

Evaluate cracking potential with unparalleled precision using our meticulously engineered Shrinkage Ring Assemblies. Designed specifically for restrained shrinkage testing of mortar and concrete specimens, these rings deliver consistent, reliable data on tensile stress characteristics and cracking age. Manufactured to strict specifications in full compliance with ASTM C1581 and AASHTO T334-08 standards, our Shrinkage Rings provide researchers and quality control professionals with definitive insights into material performance under real-world conditions.

Datasheet can be downloaded from the documents section.

Shrinkage ring prices depend on dimensions, material grade, and any custom machining requirements.

Data Sheet

| Parameter | Value |

|---|---|

| Inner & Outer Diameter |

Accurate ID and OD ensure a tight interference fit between the shaft and the mounted component. |

| Material | Manufactured from high-grade alloy steel or stainless steel for superior strength and durability. |

| Hardness |

Typically 50–60 HRC, providing excellent wear resistance and long service life. |

| Wall Thickness | Designed to withstand high compressive forces during shrink fitting without deformation. |

| Surface Finish & Tolerance | Precision-ground surfaces with tight tolerances (e.g., ±0.01 mm) ensure reliable strain measurements |

| Base Plate Material | Polypropylene |

Evaluate cracking potential with unparalleled precision using our meticulously engineered Shrinkage Ring Assemblies. Designed specifically for restrained shrinkage testing of mortar and concrete specimens, these rings deliver consistent, reliable data on tensile stress characteristics and cracking age. Manufactured to strict specifications in full compliance with ASTM C1581 and AASHTO T334-08 standards, our Shrinkage Rings provide researchers and quality control professionals with definitive insights into material performance under real-world conditions.

Datasheet can be downloaded from the documents section.

Shrinkage ring prices depend on dimensions, material grade, and any custom machining requirements.